BGA REBALLING & REPLACEMENT

The Laptop Specialist

BGA REBALLING & REPLACEMENT

BGA REBALLING & REPLACEMENT

Taken a big leap in portable computing products

Company has transformed itself from a small business into a very large

We have a strong team of good professionals, who are empowered to act independently and swiftly to ensure highest level of customer satisfaction enables us to offer our valuable customers.

One way to resolve GPU chip problem is to reball the chips themselves. Many service centers reflow the chip, as we used to.

The reason behind the failure itself justify the success of Reballing.

Thermal cycling cause the following in Lead-Free Solder over time.

- Weak bonds

- Solder Voids

- Organic Matter Build Up

- Cracking Brittle Joints

- “Black pad” caused by the formation of brittle intermetallic layers

- Pad Cratoring, It is the space left vacant when a BGA ball pad lifts off the board.

All of these are caused by the solder going through so many thermal cycles due to the lack of heat dispersion, simply put the solder spheres are too old and have been through too much.

The affects of thermal cycling on BGA packages have increased since regulations were put into place concerning consumer electronic and the use of Leaded solder. This meant that all consumer electronic items must only use Lead-Free solder which is much more brittle and affected by thermal cycling.

Therefore replacing the solder is the best route, also to reduce the damage each thermal cycle causes we have fabricated a heat sink modification to reduce the run heat of the GPU by 30%.

We also replace them with Leaded Solder balls these are less prone to the affects of thermal cycling.

Please note due to the ever changing physical size of BGA packages not all can be reballed, but we have found a succesful way of serviceing those at a high level.

EXAMPLES OF BGA ICS WE HAVE REBALLED.

NO FIX NO FEE REDUCTION

Majority of our No Fix No Fee and Warranty return Laptops are due to BGA IC’s related issues.

BGA IC’s include Graphics IC’s, Northbridge, Southbridge, RAM IC’s, CPU’s, Network Controllers, Sound IC’s, etc.

Unfortunately BGA Packages are becoming more and more popular with manufacturers.

We are implementing a process to help reduce our No Fix No Fee and Warranty Return Rate. These are currently in par with industry standards, which we are constantly striving to reduce.

Not all BGA Package IC’s can be Reballed, this is due to the size and thickness of the BGA IC’s. Thinner and more fragile BGA IC’s are more prone to warping and will not fit back flush onto the motherboard.

Therefore we carefully reflow them under custom made reflow profiles. We also use our own formulated flux which was developed by the patent holders of Infra red Rework Stations. (not the gunky yellow flux other serviceers use, which leaves a nasty residue and can cause further issues).

All other BGA IC’s are Reballed and fitted back on the board. Again using custom made reflow profiles and flux.

Now here is the tricky part. The combination of Reflow and Reballing works 80% of the time without failure.

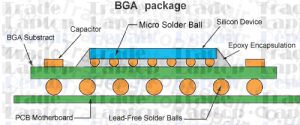

The reason they fail or do not work initially (No Fix No Fee) is because there are two layers of solder balls in majority of all BGA IC packages.

The BOTTOM layer can be seen and Reballed, the TOP layer are micro balls sealed under the top Silicon Device of the BGA IC Package.

As the diagram above shows these Micro Solder Balls are encapsulated and sealed thus rendering it impossible to remove and Reball, Noone can Reball these. Though they are NOT AS susceptible to the effects of thermal cycling due to being sealed, they do fail that very small percentage of the time therefore the only option is to replace the BGA IC altogether.

This is the reason for Reballed laptops returning under warranty. No one can tell if the TOP layer of solder balls are faulty until unless it fails at least twice under warranty.

Therefore we are proposing to replace faulty BGA IC’s, we will advise on an individual service basis. Please note that the cost of a replacement BGA IC will be added to the Fixed Rate Motherboard Service Fee. Typically £10-20, we will advise of the costing and lead time.

Our first priority will be to service the laptop under the Fixed Rate Fee i.e Reflow or Reballing and only a fraction will need to be quoted for extra BGA IC costs. This is to keep cost for you to a minimum.

Please note we shall also be advising and quoting customers to replace BGA IC’s if we believe the BGA IC is faulty. This applies for New Services and Warranty Services.

System dead.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

No display.

Dim Display problems are usually caused by a faulty inverter or Cold Cathode Fluorescent Lamp

System getting mute.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

System getting hang.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Keyboard control section problem.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Memory control section problem.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Audio not working.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

USB port not working.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Serial port not working.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

CD Drive control section problem.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Hard disk control section problem.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

Hard disk control section problem.

Lorem ipsum dolor sit amet, consectetur ipsum dolor sit amet

-

Call Us Today

+919500066668 / +919003166661

-

write at any time

[email protected] -

Visit Our

Store Locators